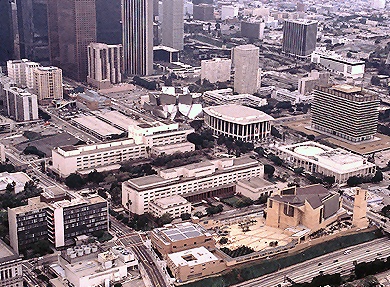

Our Lady of the Angels Cathedral - Los Angeles, California

Massive cathedral that boasts 25,000 pound bronze doors, a 70-foot high concrete cross behind the alter and seating capacity for 3,000.

Our Lady of the Angels Cathedral - Los Angeles, California

This massive concrete structure is the third largest cathedral in the world and the first to be built in the United States in over a quarter of a century.

Third Largest Cathedral in the World, 2002

Conceived by Cardinal Roger Mahoney, this massive concrete structure is the third largest cathedral in the world and the first to be built in the United States in over a quarter of a century. Cardinal Mahoney dreamed of a cathedral that would rival any of the wonders in Europe, that would stand for centuries and give comfort to all who entered its doors. He believed the only way to achieve his dream was to find people who could truly work together as a team on this immense project, and so Mahoney carefully chose design architect Jose Rafael Moneo, executive architect Leo A. Daly, structural engineer Nabih Youssef and the concrete contractors from Morley Construction Company.

First came the design problems. The original design of Our Lady of the Angels cathedral was based on a complex coordination system that didn't readily lend itself to building forms and positioning reinforced steel. Because of that, the design had to be converted to true dimensions. The new design incorporated information for the embedded elements, making the job much easier for everyone involved.

Because the cathedral was to be located in California, it was imperative that the structure be resistant to earthquakes. To achieve this, Youssef designed 149 elastomeric base isolators that would support the 125 million pound building. These isolators were designed allow the cathedral to move 27 inches in either direction, and moderate earthquake forces by 75%. If this system was not in place, the cement walls would likely crack during a quake.

Most concrete contractors will tell you that the majority of jobs are about columns and decks. The cathedral was all about the walls. Its walls are as high in some places as 130 feet, made of lightly sandblasted concrete, and vary in thickness from one to five feet. The concrete contractors used highly fluid concrete, poured into watertight forms in order to achieve uniform color consistency. The corners were so sharp and perfectly consolidated that visitors to the site thought they were precast.

Perfect was the buzzword on this project. With up to 15 ten-man crews working simultaneously, the walls were numbered and every detail had to be signed off on by the structural engineer and architect before they could even be poured. And most perfect-and challenging-of all was the 70-foot high concrete cross behind the alter. It weighs in at almost 2 million pounds and is supported only by the arms, which is actually a nine inches / foot wall tied into the 17 foot deep main concrete girders.

The cathedral boasts 25,000 pound bronze doors, a steeply pitched entrance hall, and seating capacity for 3,000. Also on the site are an educational center, a 156 foot tall bell tower, and a 2 ½ acre outdoor plaza. Cardinal Mahoney resides on the grounds of the cathedral he dreamed of, planned for, and oversaw for the three years it took to complete at a total cost of $200 million.